Custom die cutting is a fascinating process that allows businesses and individuals to create uniquely shaped materials with precision and efficiency. This technique is widely used in various industries, from packaging and marketing to manufacturing and crafts. Understanding the ins and outs of custom die cutting can open up a world of creative possibilities and practical applications.

What is Custom Die Cutting?

Custom die cutting is a manufacturing process where a machine cuts, shapes, or forms materials using a specially designed tool called a die. The die is crafted to match the specific design requirements of a project, enabling the production of items with consistent shapes and sizes. This method is particularly useful for producing high volumes of products quickly and accurately.

The Process of Custom Die Cutting

The first step in producing something using custom die cutting involves making a die. Essentially, a die refers to a mold or template whose shape and size replicate the final product. Usually one would lay the material to be cut on a flat surface before pressing the die into it leaving a precise cut-out of the desired shape. Several techniques and machines may however be applied in customizing dies due to their nature and intricacy.

Types of Die Cutting Machines

These are a bunch of different types of die cutting machines, each of which is designed for a special purpose and use papers and boards. Some of the most common include:

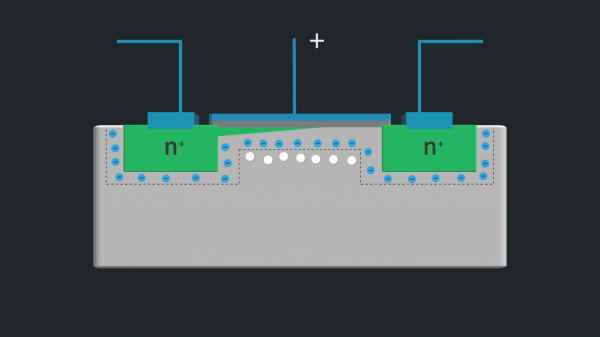

- Rotary Die Cutting: The material is cut using a rotating cylindrical die in this method, which is perfect for large-scale production and capable of processing various materials such as paper, cardboard and plastic.

- Flatbed Die Cutting: In this technique, a flat die is pressed down onto the material using a press. It is well-suited for thicker materials and projects that require intricate designs.

- Digital Die Cutting: This method uses digital files and a computer-controlled machine to cut the material. It is perfect for custom projects that require flexibility and precision without the need for a physical die.

Materials Used in Custom Die Cutting

There are many materials that can benefit from custom die cutting because it can be used on materials in many industries and as a result, it is versatile. Common materials include:

- Paper and Cardstock: Widely used in the printing and packaging industries for creating labels, packaging inserts, business cards, and more.

- Plastic: Used for creating custom shapes in signage, promotional items, and packaging.

- Fabric and Textiles: Applied in the fashion and automotive industries for cutting patterns and components.

- Foam: Utilized in packaging, insulation, and protective products.

Applications of Custom Die Cutting

The versatility and precision of custom die cutting make it suitable for numerous applications across different industries. Some of the most popular uses include:

Packaging

Custom die cutting is extensively used in the packaging industry to create boxes, inserts, and displays that are both functional and visually appealing. Die-cut packaging can be tailored to fit specific products, providing protection and enhancing the unboxing experience.

Marketing and Promotional Materials

Custom die cutting is commonly used by businesses for producing unique designs in eye-catching marketing materials like stickers, brochures, business cards, promotional items; this helps companies be remembered with their brands as stand-out brands through making something special that brings back memories in our minds by creating new shapes or designs for them.

Manufacturing

In the manufacturing sector, custom die cutting is used to produce components and parts with high precision. This is crucial for industries like automotive, electronics, and aerospace, where accuracy and consistency are paramount.

Crafting and DIY Projects

Custom die cutting helps hobbyists and crafters achieve complicated patterns for making scrapbooks, cards, and doing similar things by themselves. Custom All these DIY projects range from scrapbooks to gift cards tore display boards made through die-cutting are the hobbies of many people. Descriptive words or illustrations are in print media as well as magazines in order to make them attractive.

Benefits of Custom Die Cutting

The advantages of custom die cutting are numerous, making it a preferred choice for many projects. Some key benefits include:

Precision and Consistency

Custom die cutting allows for the production of items with exact dimensions and shapes, ensuring uniformity across large quantities. This is essential for maintaining quality and consistency in products.

Efficiency

The process is extremely efficient and it can enable one to quickly produce large volumes of items in a very short time. Therefore, it is suitable for sectors where quick turnaround times are required while maintaining high levels of productivity.

Versatility

Applying custom die-cutting on diverse materials and projects endows a wide range of industries and applications with a versatile option. This adds more value by allowing for custom shapes and designs to be made easily.

Cost-Effectiveness

Although the upfront cost of producing a tailored die might seem steep, the resulting cost of money in the long run will indeed be enormous. Not only can you use the die several times once created, but this helps cut on production expenses and minimizes garbage.

Choosing the Right Custom Die Cutting Service

It is essential to pick the appropriate custom die cutting service if your project is to succeed. Consider the following factors when making your choice:

Expertise and Experience

When looking for service providers, always ensure to look out for one that has proven records in die cutting customization and possesses expertise in it. Your project would greatly benefit from the advice and suggestions of skilled people.

Quality and Precision

Ensure that the service provider uses high-quality materials and equipment to achieve precise and consistent results. Ask for samples or references to verify their capabilities.

Customization Options

Choose a service that offers a range of customization options to meet your specific needs. This includes the ability to handle different materials, sizes, and design complexities.

Customer Support

Good customer support is essential for a smooth and successful project. Select a service provider that is responsive, communicative, and committed to meeting your deadlines and requirements.

Conclusion

Custom die cutting is a powerful and versatile process that offers numerous benefits across various industries. From packaging and marketing materials to manufacturing components and crafting projects, the precision and efficiency of custom die cutting make it an invaluable tool. By understanding the process and selecting the right service provider, you can harness the full potential of custom die cutting to achieve your creative and practical goals.

You must be logged in to post a comment Login